1. Sembrani neodymium biasane digawe saka alloy powdered saka neodymium, wesi, lan boron sing sintered bebarengan ing dhuwur panas lan meksa kanggo mbentuk produk rampung.

2. Campuran wêdakakêna dilebokake ing cetakan utawa wadhah lan dipanasake nganti suhu sing luwih dhuwur supaya mulai leleh lan gabung.

3. Sawise materi tekan titik leleh, ditahan ing suhu iki kanggo sawetara wektu nganti solidifies dadi siji Piece tanpa kesenjangan utawa retak antarane partikel.

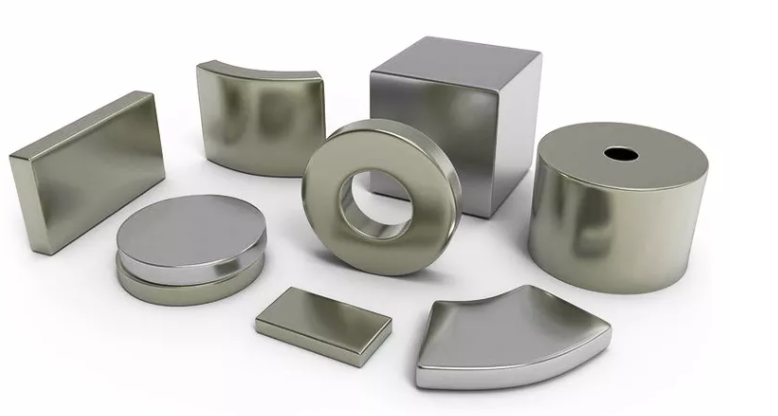

4. Sawise solidification wis dumadi, sembrani bisa machined menyang wangun lan ukuran sing dikarepake nggunakake macem-macem alat nglereni kayata mesin panggilingan utawa lathes gumantung ing specifications aplikasi.

5. Ing pinggiran sembrani banjur bisa polesan Gamelan yen dikarepake sadurunge kang ditutupi karo plating protèktif kayata nikel utawa seng kanggo tujuan resistance karat.

Rincian liyane pangolahan, please kindly ndeleng bagan alur ing ngisor iki:

| Ora. | Alur Proses | Langkah Produksi | Operasi Teknologi |

| 1 | Inspeksi Bahan Baku | 1.ICP-2.Analisis kimia-3.Analyser(C&S) | Deteksi Rohs Test Komposisi Analisis Kemurnian |

| 2 | Pre-treatment Bahan Baku | 4. Sawing- 5. Pangatusan- 6. Impact Cleaning | Sawing Iron Pangeringan Udara Panas Impact Cleaning |

| 3 | Kontrol Bahan | 7. Kontrol bahan | Timbang Batching Campuran Bahan Mentahan |

| 4 | Casting Strip | 8. Vacuumizing-9. Leleh-10. Casting | Vacuumizing Lebur Peleburan Casting |

| 5 | Hidrogen Decrepitation | 11.Pre-treating-12.Vacuumizing-13.Tambah Hidrogen | Pre-treating Vacuumizing Mbusak dening Hidrogen |

| 6 | Penggilingan | 14.Shattering-15.Grinding-16.Jet Mill-17.Granularity Control | Ngrusak mecah Jet Mill Pengukuran Rogular |

| 7 | menet | 18. Bobot bubuk -19.Pre-pressing - 20.Presing -21. Tekanan isostatik | Bobot bubuk Pre-pressing menet Tekanan isostatik |

| 8 | Sintering | 22. Vacuumizing- 23. Sintering -24 Perawatan panas | Vacuumizing Sintering perawatan panas |

| 9 | Inspeksi | 25. BH kurva-26. PCT-27. Test Kapadhetan -28.Roughcast Inspection | Pangukuran magnetik Tes koefisien suhu PCT Pangukuran Kapadhetan Inspeksi |

| 10 | Mesin | 29.Grinding -30.Wire cutting-31.Inner blade cutting | mecah Pemotongan kawat Pemotongan blade batin |

| 11 | Tes sampel QC | 32. uji sampel QC | Tes sampel QC |

| 12 | Chamfering | 33. Nglembur | Chamfering |

| 13 | Electroplating | 34. Electroplating Zn 35. Electroplating NICUNI 36. Phosphating 37. Kimia Ni | Electroplating Zn Electroplating NICUNI Fosfat utawa Kimia Ni |

| 14 | Inspeksi Coating | 38. Kekandelan-39. Tahan Korosi -40. Adhesiveness-41.-Toleransi pengawasan | kekandelan Tahan karat Adhesiveness Inspeksi Toleransi |

| 15 | Magnetisasi | 42. Inspeksi Lengkap- 43. Marking- 44. Arraying / Involution- 45. Magnetizing | Inspeksi Lengkap menehi tandha Arraying / Involusi Magnetizing Test Fiux Magnetik |

| 16 | Packing | 46. Fluks Magnetik- 47. Bagging- 48. Pengemasan | Bagging Packing |

Wektu kirim: Feb-15-2023